Do you want eye-popping, durable prints for everything from custom tees and phone cases to drinkware and home accessories? Sublimation printing might be your new best friend! This flexible technique can help you print highly-detailed designs on metal, ceramic, mouse pads, and more. Get ready as we dive into the magic of sublimation, breaking down what it is, how it works, its benefits and drawbacks, and the top products you can create.

Whether you’re just starting out or looking to scale, this guide will help you unlock the full potential of sublimation printing. We’ll also show you how MyDesigns can help you kickstart and scale your sublimation print-on-demand brand.

Let’s dive in!

Table of Contents

What Is Sublimation Printing?

Sublimation printing (also known as dye-sublimation) is a process of printing designs onto surfaces using special inks that turn into gas under heat, bonding with the material at a molecular level. In simple terms, the design doesn’t just sit on top of the substrate (as with vinyl or screen prints) – it becomes part of the material. This is achieved by first printing the artwork on transfer paper with sublimation inks, then using high heat to vaporize the ink into the fibers or coating of the product. The result is a permanent, full-color print that won’t crack or peel because the ink is infused into the item.

Sublimation printing (also known as dye-sublimation) is a process of printing designs onto surfaces using special inks that turn into gas under heat, bonding with the material at a molecular level. In simple terms, the design doesn’t just sit on top of the substrate (as with vinyl or screen prints) – it becomes part of the material. This is achieved by first printing the artwork on transfer paper with sublimation inks, then using high heat to vaporize the ink into the fibers or coating of the product. The result is a permanent, full-color print that won’t crack or peel because the ink is infused into the item.

In short, sublimation printing is ideal for producing photo-quality, all-over prints on suitable materials, making it a go-to for many POD products.

How Does Sublimation Printing Work?

A large format sublimation printer is printing a full-color design onto special transfer paper. After printing, the paper will be heat-pressed onto fabric, causing the ink to sublimate (turn into gas) and bond with the fibers. This process enables vibrant, edge-to-edge prints on apparel.

A large format sublimation printer is printing a full-color design onto special transfer paper. After printing, the paper will be heat-pressed onto fabric, causing the ink to sublimate (turn into gas) and bond with the fibers. This process enables vibrant, edge-to-edge prints on apparel.

Sublimation printing involves a few straightforward steps:

Design Creation

Prepare a digital design or artwork on your computer. This can be anything from text and graphics to photographs. The design is usually mirrored (especially for text) since it will be flipped during transfer.

Print onto Transfer Paper

Using a dedicated sublimation printer loaded with sublimation dye inks, print the mirrored design onto special sublimation transfer paper. The inks will look dull on the paper – this is normal, as they activate under heat.

Prep the Substrate

Ensure the item to be printed (shirt, mug, etc.) is sublimation-friendly (e.g. polyester fabric or polymer-coated surface) and prepped. For fabrics, lint-roll and pre-press to remove moisture; for hard goods like mugs, make sure they are clean and dry.

Heat Press Transfer

Place the printed transfer paper onto the item (ink side against the substrate). Using a heat press, apply firm pressure at high temperature (around 375–400°F or ~190–205°C) for a specific time (often ~30–60 seconds for fabric, a few minutes for ceramics). The heat and pressure sublimate the ink – turning it into a gas that penetrates the material.

Cool and Finish

Remove the paper (caution: it’s hot!). The design has now transferred fully. Let the product cool down. The dyes solidify back into the material, resulting in a permanent image. After cooling, the item is ready to use with no additional curing needed.

During this process, the solid ink effectively skips the liquid phase and goes straight to gas, bonding with the polymers in the substrate.

The key equipment and materials required for sublimation include:

- A sublimation printer (or converted inkjet printer) with the correct ink

- Compatible transfer paper

- A reliable heat press (flat press for apparel, mug press or oven for drinkware)

- Heat-resistant tape (to hold transfers in place)

- Sublimation-ready blanks (products made of or coated with polyester)

With the right setup, you can go from a digital design to a finished, custom-printed product in just minutes.

Benefits of Sublimation Printing

Why do so many businesses choose sublimation for custom products? Sublimation printing offers several key advantages over other techniques:

Vibrant, Photographic-Quality Prints

Sublimation delivers outstanding image quality. You can reproduce full-color photographs, intricate patterns, and fine details with ease. The colors come out vibrant and sharp, with smooth gradients and no obvious dot pattern. Unlike screen printing, there’s no limit to the number of colors.

Sublimation delivers outstanding image quality. You can reproduce full-color photographs, intricate patterns, and fine details with ease. The colors come out vibrant and sharp, with smooth gradients and no obvious dot pattern. Unlike screen printing, there’s no limit to the number of colors.

Durable and Long-Lasting

Because the ink actually becomes part of the material, sublimated prints are extremely durable. The design won’t crack or peel over time, and it resists fading from washing. For example, on fabric the dye penetrates the fibers, so the print stays intact and colorful even after dozens of wash cycles.

No Feel on Fabric

Printed apparel retains its original softness because there’s no thick ink layer on top. With sublimation, the fabric’s fibers are dyed, so the print feels as smooth as the garment itself. This is a big plus for all-over t-shirts, leggings, or socks – the design is vibrant but you literally can’t feel any print when you touch the fabric.

On-Demand and Small Batch Friendly

Sublimation has virtually no setup cost per design. You don’t need to burn screens or mix inks for each print. Whether you’re printing 1 item or 100, the process (and cost per item) is roughly the same, making it fantastic for one-off orders or short runs. This is why sublimation is so popular in POD – you can profitably print single items.

Versatile Range of Products

Unlike some methods that are mostly for T-shirts, sublimation is useful across a wide range of products. You can decorate polyester apparel, but also hard goods like mugs, phone cases, mouse pads, metal photo panels, and more – all with the same printer and inks. This allows a POD business to expand into many categories (drinkware, home décor, accessories, etc.) using one printing technique.

Unlike some methods that are mostly for T-shirts, sublimation is useful across a wide range of products. You can decorate polyester apparel, but also hard goods like mugs, phone cases, mouse pads, metal photo panels, and more – all with the same printer and inks. This allows a POD business to expand into many categories (drinkware, home décor, accessories, etc.) using one printing technique.

Clean and Efficient

Sublimation is a relatively clean process. There’s no excess ink to dispose of (the ink that isn’t transferred stays on the paper, which can be thrown away). Since it’s all digital, you only use the amount of ink needed for the print, leading to minimal waste. There are no screens or emulsions to wash out as in screen printing, and no pretreatment chemicals as in DTG. This can make it a bit more eco-friendly and hassle-free in a small studio setting.

These advantages make sublimation a compelling choice for many POD entrepreneurs who want a combination of quality, flexibility, and ease of use in producing custom products.

Limitations and Challenges

No printing method is perfect – and sublimation does come with some limitations and challenges to be aware of:

Material Constraints

Sublimation only works on certain materials. Specifically, you’ll get the best results on items made of polyester or coated with a polyester/polymer layer. You cannot sublimate on 100% cotton or other natural fabrics, as the dye won’t bond. For hard goods like ceramics, wood, or metal, they must have a special poly coating to accept the sublimation dye. This means your product selection is a bit restricted to polyester-based blanks.

Light Colors Only (No White Ink)

Sublimation cannot print white color. The process relies on the base material for any white or light areas in the design. Standard sublimation inks are CMYK, so there’s simply no white pigment. As a result, sublimation is effective only on white or light-colored substrates. If you use a dark or black shirt, the colors won’t show up correctly. This is a major limitation compared to, say, screen printing which can use white ink on dark garments.

Requires Specialized Equipment

To do sublimation, you need some dedicated gear up front – a printer with sublimation ink, and a heat press that can reach high temperatures. While entry-level sublimation setups are not as expensive as industrial DTG printers, it’s still an investment to get a good printer, inks, a quality heat press, etc. Additionally, each type of product might need extra accessories (e.g. a mug press or convection oven for drinkware, jig templates for phone cases, etc.).

Despite these challenges, most can be mitigated. Sticking to polyester blanks and light colors, investing in good equipment, and practicing the craft will ensure you get excellent results. And for many POD businesses, the ability to create high-quality one-off products easily outweighs the limitations.

Sublimation Printing vs DTG and Screen Printing

| Feature | Sublimation Printing | Screen Printing | DTG Printing |

|---|---|---|---|

| Process | Uses heat to turn dye on transfer paper into a gas that fuses with polyester or polymer-coated surfaces. | Uses a mesh screen and stencil to push ink onto the material; each color requires a separate screen. | Sprays textile inks directly onto garments via a specialized inkjet printer, often with a white underbase for dark items. |

| Materials Used | Sublimation dyes, transfer paper, and substrates with polyester content or a special coating. | Plastisol or water-based inks, screens, and emulsions; works on a variety of fabrics, including cotton. | Textile inks (CMYK + white) that work best on cotton or cotton blends; dark garments need pretreatment. |

| Setup Cost | Minimal per-design cost; no screens required, just a sublimation printer and heat press. | Higher setup cost due to creating screens for each design and color; ideal for large orders. | Moderate setup cost; requires a dedicated DTG printer and additional pretreatment steps for dark garments. |

| Production Efficiency | Excellent for one-offs and small batches; quick turnaround per item though limited by substrate size. | Best for bulk production once screens are set up; not cost-effective for short runs. | Great for on-demand, low-to-medium volume orders; can be slower per item compared to screen printing. |

| Color Quality | Delivers vibrant, full-color, photorealistic prints with smooth gradients that become part of the material. | Produces solid, opaque colors with excellent matching, though complex gradients can be challenging. | Offers high-resolution, detailed prints, ideal for photographic images and intricate designs. |

| Print Durability | Highly durable prints since the dye is fused into the substrate, so they won’t peel or fade. | Prints are very durable if cured properly; however, thick ink layers can sometimes feel heavy. | Generally durable when cured correctly, though dark garments may require extra care to maintain quality. |

| Substrate Compatibility | Works only on polyester fabrics or polymer-coated items; best on light-colored substrates. | Versatile – can be used on cotton, polyester, and many other materials; suitable for both dark and light items. | Best suited for cotton and cotton blends; works on dark garments with pretreatment, but limited to fabric items. |

| Suitable For | Perfect for full-color, detailed designs on custom apparel, drinkware, and various hard goods. | Ideal for large orders of simple, solid-color designs such as logos on a variety of products. | Excellent for on-demand custom apparel, especially when you need photo-quality prints on fabric. |

| Feel of Print | The dye fuses with the material, leaving no added texture – you can’t even feel the print. | The ink sits on top, sometimes creating a slight raised or textured feel on the fabric. | The ink is absorbed into the fibers, so prints feel soft, though heavy white ink on dark garments may be a bit noticeable. |

Best Products for Sublimation Printing

One of the greatest strengths of sublimation is the wide array of products you can create. Here are some of the best and most profitable product categories for sublimation printing:

Polyester Apparel

Sublimation is hugely popular for printing on clothing made of polyester or poly-blends. Think all-over print T-shirts, sports jerseys, hoodies, leggings, swimwear, and socks. Since the dye becomes part of the fabric, the prints on these garments are vibrant, breathable, and durable.

Mugs & Drinkware

Personalized mugs are a top-selling item in POD, and sublimation is the go-to method for printing them. You can sublimate on ceramic mugs, stainless steel tumblers, enamel camp mugs and similar items. Drinkware is popular because it makes an excellent gift item – people love mugs with custom images or artwork. The sublimation process produces photo-quality images on mugs that are dishwasher-safe and never peel off.

Personalized mugs are a top-selling item in POD, and sublimation is the go-to method for printing them. You can sublimate on ceramic mugs, stainless steel tumblers, enamel camp mugs and similar items. Drinkware is popular because it makes an excellent gift item – people love mugs with custom images or artwork. The sublimation process produces photo-quality images on mugs that are dishwasher-safe and never peel off.

Home Décor and Accessories

Sublimation extends into a variety of home and lifestyle products. For instance, you can create throw pillows and cushion covers (using polyester fabric cases), blankets and quilts (some vendors offer fleece or silky blankets ready for sublimation), wall tapestries, and even doormats with polyester tops. In the kitchen, items like polyester towels, pot holders, and aprons (with poly coating) can be sublimated.

Promotional Products & Miscellaneous

There are countless other sublimation-friendly items. Mouse pads and gaming mats (typically polyester fabric on rubber backing) sublimate very well. Keychains, coasters, luggage tags, ID badges, phone grips – if it has a poly-coated hard surface or a polyester insert, it can likely be sublimated. Phone cases often use a sublimatable metal insert that adheres to the plastic case after printing.

When choosing products for your sublimation business, consider what items align with your target market and design skills. Mugs and apparel (like tees) are broad, evergreen sellers with huge demand. Niche items like custom socks or puzzles can set your store apart if you find the right audience.

How to Start a Sublimation-Based POD Business

Getting started with a sublimation-based POD business can be very rewarding. Here’s a step-by-step roadmap to launch your own sublimation venture:

Step 1: Research Your Niche and Products

Begin by deciding what kind of products you want to sell and to whom. Will you focus on custom apparel (like trendy all-over print shirts), personalized gift items (mugs, photo panels), or a mix? Research current trends and see what’s selling well in the market. Identifying a niche (for example, funny coffee mugs or custom sports team jerseys) can help tailor your product line and designs.

Check out our guide on finding profitable niches for Etsy.

Step 2: Find Platforms that Support Sublimation Printing

Since investing in sublimation printing equipment is expensive, you can partner with a POD fulfillment service like MyDesigns that offers sublimation products. A fulfillment partner will print/ship your customers’ orders for you.If you plan to produce in-house, invest in a sublimation printer and heat press suitable for your needs. There are small format printers (prints up to letter/A4 size) which are great for mugs, small apparel prints, and accessories – these are budget-friendly for beginners.

Step 3: Create or Source Designs

Great designs are the heart of a sublimation business. If you’re artistic, you can create your own designs using graphic software or even hand-drawn art converted to digital. If not, you can hire designers or purchase design files (make sure you have the rights for commercial use).

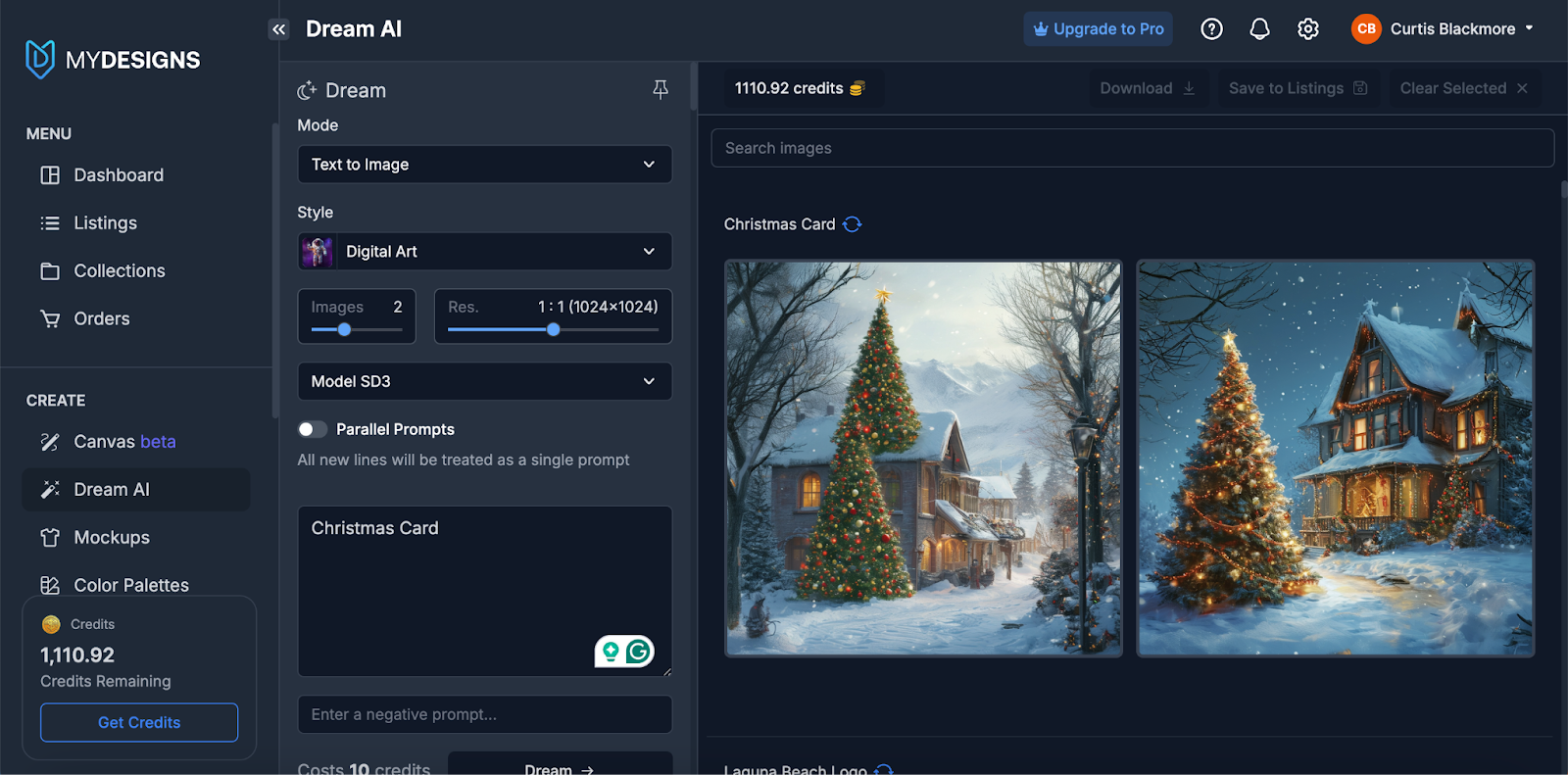

With Dream AI, you can also generate images in multiple styles with simple text prompts. Check out some of the best designs generated by MyDesigns users with Dream AI.

Step 4: Set Up an Online Store

Next, establish your sales channels. Many start with an Etsy shop because it’s a huge marketplace for personalized products. Others build a Shopify website for more control over branding. You can even do both or sell on additional platforms (Amazon Handmade, eBay, etc.). Whichever route, set up a professional-looking storefront with a clear niche and good branding.

With MyDesigns, you can connect multiple e-commerce platforms and manage bulk listing on each platform.

Step 5: Streamline Production and Fulfillment

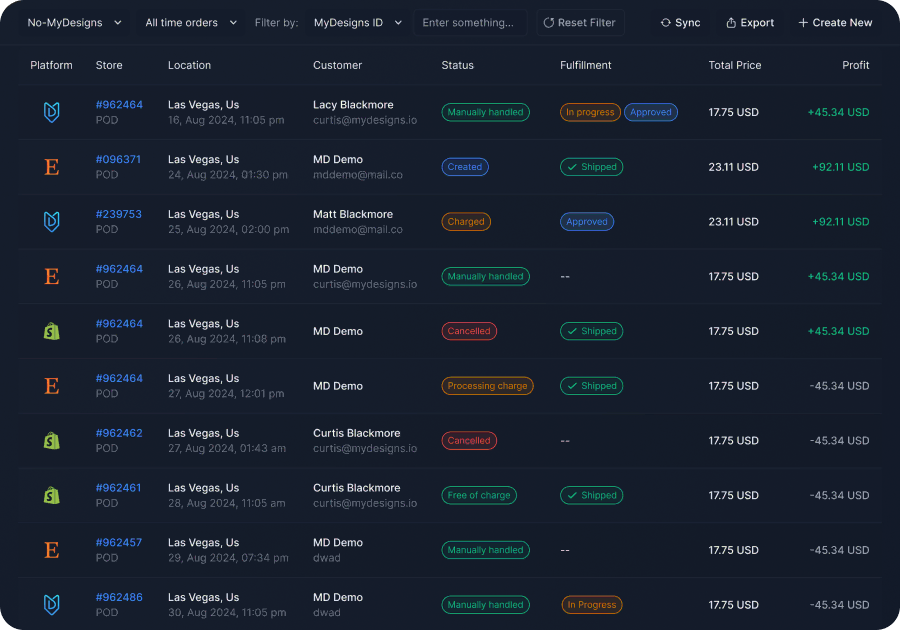

As orders start coming in, have a plan to fulfill them efficiently. MyDesigns allow you to manage orders from multiple marketplaces in one dashboard and even automatically send order details to connected print providers. As you grow, such tools can help you keep things organized – automatically updating tracking numbers, syncing inventory, etc., reducing manual errors.

Step 6: Marketing and Scale-Up

With your sublimation business launched, focus on marketing and scaling. Utilize social media to show off your designs (Instagram, TikTok videos of the making process can be engaging). Consider running ads for your best-selling items. Encourage customers to post photos of their products (user-generated content is powerful for attracting new buyers). Continuously analyze which designs or products are performing well and iterate – add new designs in that style or expand that product line.

Check out our guide on how to go viral on TikTok in 2025.

Starting a sublimation business has a learning phase, but with the right approach it can be profitable and relatively low-risk. You can start small, invest gradually, and use the flexibility of sublimation to carve out your own niche in the custom products market.

How MyDesigns Can Help Streamline Sublimation Printing

Running a POD business – especially one offering many sublimated products – can become complex. This is where MyDesigns can be a game-changer for e-commerce entrepreneurs. MyDesigns offers a suite of features tailor-made to simplify and scale your sublimation workflow:

AI-Powered Design Generation

Creating fresh designs regularly is key to success. MyDesigns Dream AI feature allows you to generate unique artwork in seconds using simple prompts. Instead of spending hours in Photoshop or paying designers, you can describe a concept (e.g. “vintage baseball theme mug design” or “floral pattern for all-over leggings”) and let the AI produce multiple design variations.

Creating fresh designs regularly is key to success. MyDesigns Dream AI feature allows you to generate unique artwork in seconds using simple prompts. Instead of spending hours in Photoshop or paying designers, you can describe a concept (e.g. “vintage baseball theme mug design” or “floral pattern for all-over leggings”) and let the AI produce multiple design variations.

You can choose from multiple state-of-the-art image generation models within Dream AI, for example Ideogram Models (v1, v1 Turbo, v2, v2 Turbo), FLUX Series (FLUX.1 [pro], FLUX1.1 [pro], FLUX.1 [dev], FLUX.1 [schnell]), Recraft v3, Dall-E 3 and SDXL. Learn more about the image generation models supported by Dream AI.

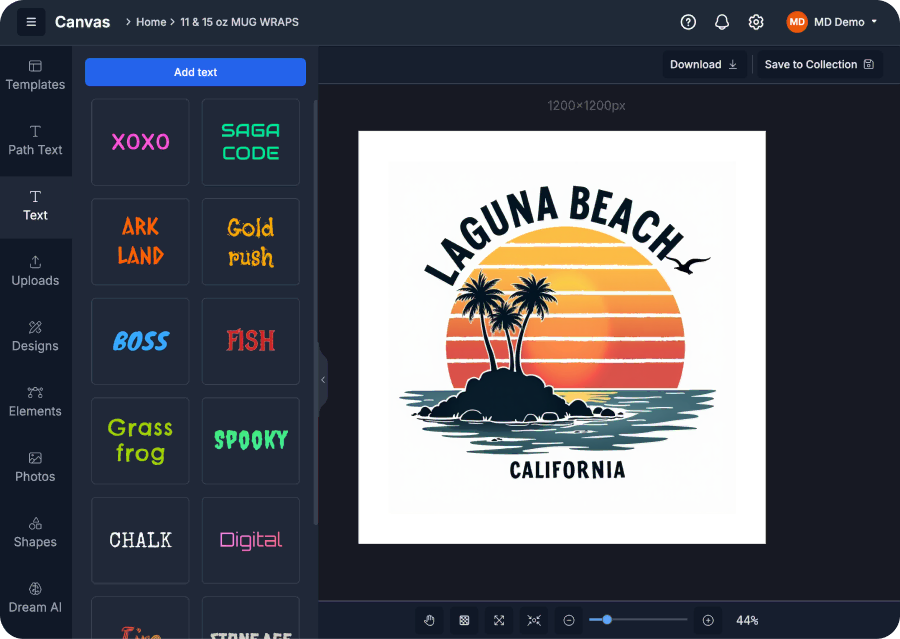

Easy Design Customization & Scaling

Once you have designs, MyDesigns makes it easy to adapt and customize them for different products. Canvas is a built-in drag-and-drop editor where you can tweak your AI-generated (or manual) designs. You can resize artwork to fit various item templates, add text or personalization (like adding a customer’s name), and ensure everything is correctly positioned.

Once you have designs, MyDesigns makes it easy to adapt and customize them for different products. Canvas is a built-in drag-and-drop editor where you can tweak your AI-generated (or manual) designs. You can resize artwork to fit various item templates, add text or personalization (like adding a customer’s name), and ensure everything is correctly positioned.

Bulk Publishing

MyDesigns really shines in handling the tedious parts of e-commerce – creating listings, writing descriptions, and publishing to multiple platforms. The platform supports bulk listing creation, meaning you can prepare dozens or hundreds of product listings and publish them all at once to your store (integrated with Etsy, Shopify, Amazon, etc.).

Instead of manually copying and pasting titles, descriptions, and uploading images for each product, MyDesigns lets you do it in a fraction of the time. You can automatically populate SEO-friendly titles and tags using AI.

Order Fulfillment

When orders roll in, MyDesigns helps ensure they are processed smoothly. The platform can connect directly with multiple fulfillment partners that offer sublimation product printing. Through MyDesigns order management system, an incoming order can be automatically routed to your chosen production partner for printing, without you needing to manually re-enter details.

When orders roll in, MyDesigns helps ensure they are processed smoothly. The platform can connect directly with multiple fulfillment partners that offer sublimation product printing. Through MyDesigns order management system, an incoming order can be automatically routed to your chosen production partner for printing, without you needing to manually re-enter details.

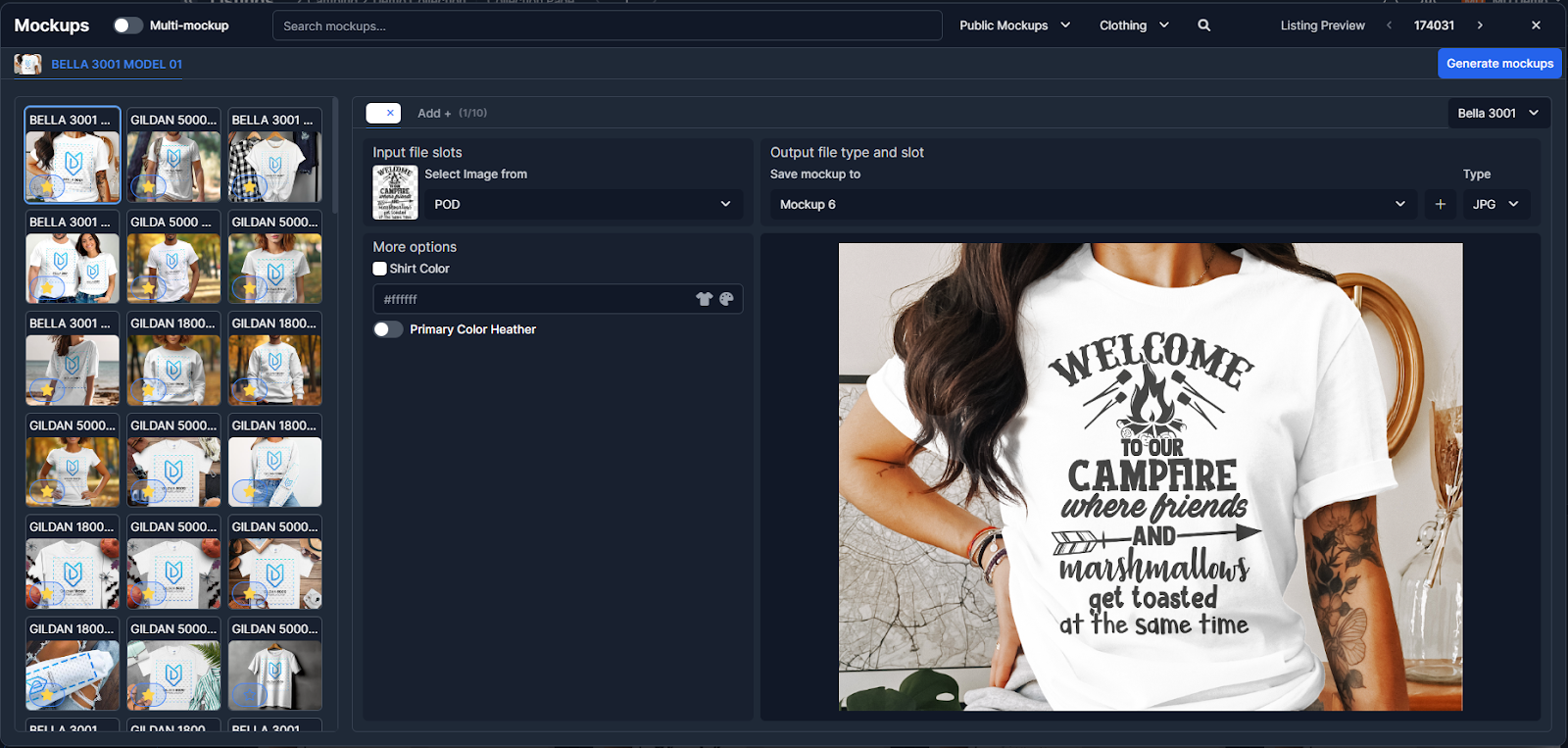

Mockups and Other Features

Additionally, MyDesigns includes handy features like a bulk mockup generator (to create professional product images for listings without having to use external software) and support for multi-product listings (where you can group variations like shirt, hoodie, mug in one listing). These features further streamline the work involved in presenting and selling your sublimation products. The platform is continuously adding integrations and tools, meaning as an entrepreneur you always have cutting-edge tech on your side.

Additionally, MyDesigns includes handy features like a bulk mockup generator (to create professional product images for listings without having to use external software) and support for multi-product listings (where you can group variations like shirt, hoodie, mug in one listing). These features further streamline the work involved in presenting and selling your sublimation products. The platform is continuously adding integrations and tools, meaning as an entrepreneur you always have cutting-edge tech on your side.

In summary, MyDesigns can significantly reduce the manual workload in a sublimation POD business..

Conclusion

Sublimation printing is a powerful printing method that has enabled countless entrepreneurs to build thriving print-on-demand businesses. In this guide, we covered what sublimation is (using heat to bond dye into materials for permanent, full-color prints) and how it works step-by-step. We looked at the major benefits as well as the limitations like material restrictions and need for specialized equipment. You’ve seen that with sublimation you can create an array of products: from vibrant all-over apparel and mugs to home décor and niche accessories. We also outlined the steps to start your own sublimation business, emphasizing planning, practice, and smart use of tools.

As you venture into sublimation printing, remember that success comes from combining creativity with efficiency. This is where leveraging platforms like MyDesigns can give you an edge. By using automation and AI, you can scale up your offerings without scaling up your workload. Imagine having hundreds of unique, sublimated products in your shop – and managing it all seamlessly with the right software backing you up.

In closing, sublimation printing opens up a world of possibilities for custom merchandise. It empowers you to deliver products that truly resonate with customers.

Ready to take your POD business to the next level? Sign up for MyDesigns today and get up and running in no time.

Leave a Reply